Museveni orders finance ministry on food factory

The food is processed from local food crops from farmers like maize, wheat, beans, millet, soya beans, orange potatoes, ground-nuts, and sim-sim.

President Yoweri Museveni at the factory. Photos by Eddie Sssejjoba

President Yoweri Museveni has directed the Ministry of Finance, Planning and Economic Development to clear Maama Care High-Tech Nutrition Food factory to resume production, one and half years since he commissioned it in Bweyogerere Industrial Park, Wakiso district.

The $45m (sh160b) food factory, which targets manufacturing ready-to-eat nutritious and fortified foods is packaged and eaten as snacks intended to provide supplementary nutrition to emergency and disaster reliefs including refugees in Internally-Displaced camps, people with low immunity including HIV/Aids and tuberculosis patients, diabetic and pressure patients, among others.

Staff showing some of the products

The factory has however been lying idle since the President commissioned it on May 31, 2018. It halted production a week after it was commissioned after the Uganda Revenue Authority (URA) demanded that in the absence of a tax waiver implementation, it would levy Value Added Tax (VAT) and Customs, although the President had directed that the taxes be waived.

The minister of state for Finance, Planning and Economic Development (Privatization and Investment) Evelyn Anite recently said that she had received a letter from the President's office directing her and her senior, Matia Kasaija to act and ensure the factory starts production.

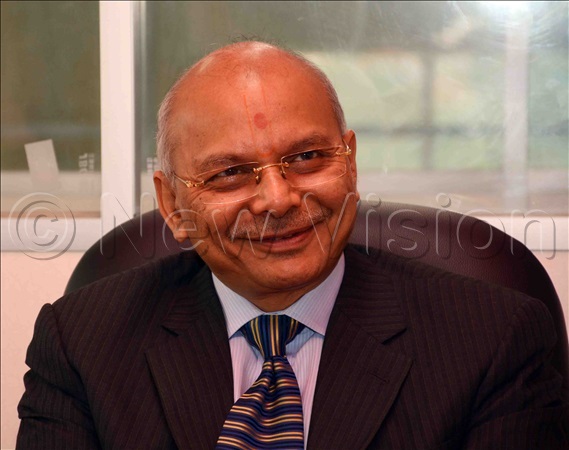

She told New Vision that the company chairman Harish Bhuptani recently wrote to the President indicating that his (President's) directive to accord them a tax waiver had not been implemented and that the machines and the entire production chain had been lying idle for one-and-half years.

The food is processed from local food crops from farmers like maize, wheat, beans, millet, soya beans, orange potatoes, ground-nuts, and sim-sim.

Other locally supplied products include honey and sugar, which are used as raw materials in the production of high vitamin value foodstuffs with the aim of addressing malnutrition in infants and school children as well as starvation amongst the populace.

The company had set up a network of farmers in various parts of the country to directly obtain supplies from the farmers.

Some of the products

It had also lined up a group of unemployed youth in the suburbs of Kampala, the disabled and other disadvantaged groups to manage their sell and supply booths in the city and its suburbs as one of the strategies to fight unemployment and help the needy.

"It is true the matter was brought to my attention and we are going to solve the problem, they must be able to resume operations soon," she said.

She added, "The investor (Bhuptani) wrote to the President about his concerns, he responded and his Principal Private Secretary has written to us in the ministry to immediately look into the issue".

She said that she had started on the process on Friday and one of her tasks was to go to URA to ensure the factory is cleared to start tax-free production as one of the incentives to enable the food to reach the market at an affordable price.

"It is within our interest that the factory is operational, my senior Matia Kasaija and I are going to work together to ensure this is expedited," Anite explained.

According to Bhuptani, through the Mama Care Foundation, founded on a Non-Government Organization and noncommercial basis, he started the factory as a way of giving back to the country. He said the total project cost is $45m (about sh160b) and the first phase is now over.

He said he had been supported by international agencies including the European Union to manufacture and supply highly nutritious foods to hospitals for the sick and refugee camps.

He said that the ‘energy bars, popularly known as rolls contain 16 different vitamins and a pack containing four rolls of the ‘NutriMeal' costs $1 (sh3,650), which will reduce to a half when the factory starts with tax-free status.

The facility, he said, has the capacity to produce over 200,000 packets of food per day or 50,000 rolls per shift. There are three shifts in a day.

The production is programmed to provide employment to the disadvantaged people in society through setting up a number of kiosks in towns throughout the country and would employ socially and economically disadvantaged groups including women and people with disabilities to manage the kiosks.

He said the government had also committed itself to buy the food and distribute it amongst hospitals and disaster-prone areas.

He said the project would be implemented in five phases and the first phase was put in place.

"We intend to recruit about 5,000, to begin with, and train them into entrepreneurship to become our agents and let them manage our booths in the city and its suburbs, with focus on women, disabled and unemployed youth," he said.

He said the company halted its production a week after the factory was opened after URA officials issued them with a tax notice.

The organization, a not-for-profit entity, would also help farmers form cooperative societies, through which they would be able to sell their produce to Maama Care Foundation.

A team of experts and parliamentarians from the Gambia in West Africa last year visited the factory after it was recommended by the Food and Agricultural Organization (FAO) and the Gambia Mission of Food Fortification.

The team was in the country for a European Union-funded five-day study tour of food fortification and bio food production in Uganda.